Ruhulla from Afghanistan has been living in Yiwu for more than ten years. He is a senior trader. He usually purchases our Chinese machinery, accessories and other products and sells them to Afghanistan and other middle eastern countries.The market is huge.

Ruhulla went to cIndy from Tubo through his other product suppliers and asked about the details of the biscuit production line and after-sales installation.We provide customers with detailed answers through emails and phone calls, one by one to solve all the mysteries in the customer’s mind.

First of all, our company’s biscuit production line has small, medium and large production lines, which can be used together with packing machine and sandwich machine.It meets the needs of customers with different investment capabilities.Ruhulla’s end customer has already owned the food processing plant, and has just entered the biscuit market with a budget of about 100,000 yuan. We recommended to him the production of 100 kg per hour of the small and medium-sized production line.

The overview of biscuit production line :

Production process:

Dough blending – roll molding – baking – spray – cooling – packaging

Main output and parameters of our company’s biscuit line:

| Host Model | LD225 | LD280 | LD400 | LD600 | |

| Power and voltage | 380V/50HZ | 380V/50HZ | 380V/50HZ | 380V/50HZ | |

| Installed Capacity | 28.5KW | 55KW | 110KW | 220kw(gast type25kw) | |

| Baking temperature | 200-300℃ | 200-300℃ | 200-300℃ | 200-300℃ | |

| Production capacity | 50~60Kg/h | 100kg/h | 150–200Kg/h | 300-500kg/h | |

| Production line length | 21000mm | 30000cm | 43000cm | 60000mm | |

Biscuit production line supporting molds:

We will provide customers with 2 sets of heat-effect pattern molds for free,customers can also choose from local markets.Some patterns (we have professional designers to make patterns, please contact tuobo business department for more patterns).

Authenticity of Tubo company:

Tubo has its own production plant, covering an area of 5000 square meters, including factory workshop, office, sample room, negotiation room and so on.Ruhulla asked for a video call with Cindy, and wanted to know about our factory.

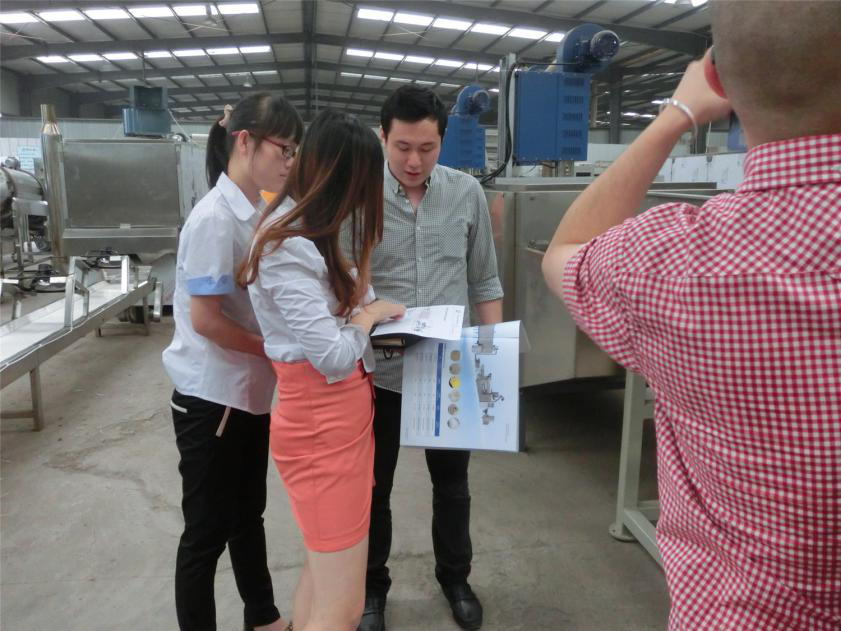

Cindy gladly accepted the client’s invitation.There happened to be a customer from Malaysia who was testing the biscuit production line. We showed the factory and the testing process to the customer. The customer felt very gratified after seeing this and finally found a suitable and reliable supplier.

Customers from Malaysia

Screen shot of factory test machine

Picture of factory site :(optimize insert)

We relayed our products to the end customer, and the factory is true and reliable, the customer is very satisfied!Next, we will negotiate the price and delivery date. Now we have provided our plan to the government department to apply for a loan, and the customer promises to place an order for cooperation within 2-3 months!