With the rapid development of social life, people love pets more and more, especially in big cities, people often feel lonely, pets are a good company for them. Therefore, pet food is becoming more and more important.

Pet food

Pet food is specially provided for pets and small animals. It is a high-grade animal food between human food and traditional animal feed.

Its main purpose is to provide a variety of pets with the most basic life assurance, growth and health needs of nutrition. It has the advantages of comprehensive nutrition, high absorption rate of digestion, scientific formula, quality standard, convenient feeding and prevention of certain diseases.

High-quality pet food not only needs to meet people’s purchase needs in appearance, but also the nutritional needs of animals are even more important. Only advanced production technology and equipment configuration can meet the high quality pet food production standards.

Pet food machine can adjust the raw materials, temperature, moisture and other technological parameters, so that the product has the characteristics of novel shape, unique taste, rich nutrition, delicate organization, suitable for different pet tastes.

Pet food production line is widely used in the production of monkey food, bird food, dog food, cat food and expanded corn, is an ideal choice for different manufacturers.

Main types of pet food puffing feed machine

At present, pet food puffing machine can be divided into single screw puffing machine and double screw puffing machine, both of which have no problem in producing pet feed with low protein and fat content.

Single screw main engine Double-screw extruder

Single screw extrusion machine on investment relative to the double screw extrusion machine has great advantage. However, due to the equipment type problem of the single-screw puffer, when producing some products with high fat and protein content, or when changing the product formula (usually defined as high-end pet food), there will be some difficult problems to solve with the single-screw puffing machine. For example, spray material, discharge instability, poor shape and so on. In addition, the workmanship is also relatively rough, the equipment in the workshop does not show classy, even if the product is well made, it is often seen as not enough decent when the customer visits the manufacturing plant, limiting the price advantage of the product.

Twin screw puffed pet food production line

Advantages of twin screw extruder

1.Double screw puffing machine operation process because of the double screw feeding, so feeding will be more smooth, more stable.

2.Double screw puffing machine after shutdown, cleaning machine is very convenient, screw with self-cleaning function, no disassembly, so relative to the single screw cleaning greatly shortened the cleaning time and labor intensity.

3.Raw materials can be added 20-40% animal viscera, chicken rack and other ground bone mud, meat mud directly expanded dog food.

4.The shortcomings of small single screw dog food machine such as insufficient swelling degree, limited proportion of adding fresh meat or bone mud, fast screw wear and high cost of late accessories are solved.

Because of this characteristic of the equipment, the twin-screw puffer is the best choice for processing pet food with high oil and protein content.

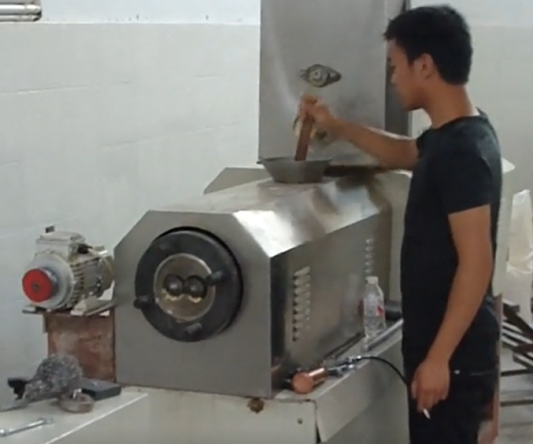

Workers operate machines

Because of the advantages of twin screw over single screw in pet food production, it is recommended to choose twin screw puffer as the preferred choice when purchasing pet food machine. Of course, twin screw investment and production costs are much higher than single screw, to consider according to the actual situation.