- Processing

- Processing PDF

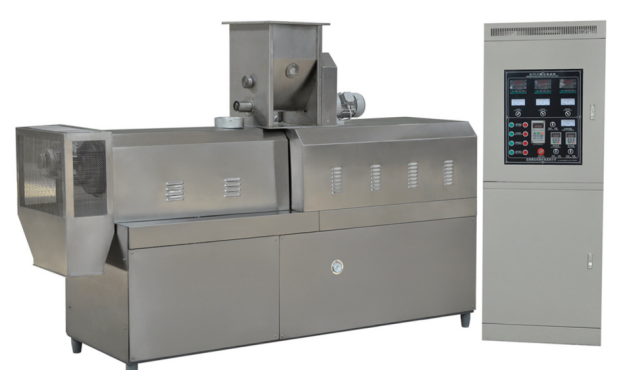

Puffed food is a kind of leisure food preferred by consumers in the market at present. To make puffed food, you need food-making machinery. The food extruder is composed of feeding system, extrusion system, rotary cutting system, heating system, transmission system and cooling system. With flour, grain powder, potato powder, all kinds of starch as raw materials, through extrusion, curing, forming, drying, puffing, produce a variety of snack food. The raw materials through different molds can produce shell, spiral, square tube, round tube, lotus root slice, thorn snail and other products with novel patterns and unique shapes; After the fried puffing, that is to become crispy and delicious, good taste food.

Food extruder

The extruder adopts screw extrusion forming technology, with various shapes of extrusion models, and then through frying, seasoning, not only retains the good taste of the handmade pasta products crisp and not greasy, but also realizes the infinite innovation of raw materials and shapes.

Puffed food produced by extrusion curing equipment

Our food extrusion machinery has the following advantages:

Our food extrusion machinery has the following advantages:

1.Our snack extrusion machine design is reasonable, strong stability, high degree of automation, advanced technology, the main machine using advanced frequency control technology, high efficiency and energy saving.

2.Recycling, drying, oil spraying, cooling, automatic one-time completion, greatly reduce the labor intensity of workers, make the product more clean and sanitary, and also greatly improve the work efficiency.

3.The service life of food puffing equipment is long, which can save labor cost greatly.

4.The delivery time is short, we have experienced workers, can manufacture food extrusion machinery in a short time.

- Single screw main engine

- Double-screw extruder

- Series puffed food extruder

- Series puffed food extruder

The food extruder equipment made in our factory is not only of good quality, but also has reasonably priced. If you need more information, please contact us.

Device parameters:

Device parameters:

| Screw diameter | 65mm/75mm |

| Main motor power | 37kw |

| Projected output | 150-300kg/h |

| Dimensions | 3.5*0.9*1.8m |

Technological flow chart:

Technological flow chart:

Mixing of raw materials → extrusion/curing molding → drying/cooling → frying/spraying/crushing → storage/packaging

Our factory has rich export experience:

Our factory has rich export experience:

We continue to improve the quality of food extruders, and a series of innovations, so that many snack food manufacturers have become our loyal customers. In recent years, our extrusion equipment has been sold to many countries in the world, including: Korea, Japan, New Zealand, Australia, Russia, the United States and many other countries. The quality of our food making machinery can completely reach the quality of similar products, and because the price is relatively low, so foreign customers like and trust.

Foreign clients visit

Then why do you choose us?

We will provide you with professional technical support:

1.Answer the questions about equipment, process, packaging and standardized layout of the workshop before the project;

2.We can experiment and demonstrate your products and process in our demonstration workshop to select suitable food extrusion and curing equipment for you.

3.According to your requirements, to provide you with efficient production system solutions.

We will provide you with thoughtful and considerate after-sales service:

1.Provide assembly line installation, commissioning services and training of operators;

2.The guarantee period of extrusion curing equipment is one year;

3.Assist you to upgrade the existing product line;

4.Provide 24-hour consultation service hotline, looking forward to your call!

Food extruder Technologies and Processing PDF Download

Food extruder Technologies and Processing PDF Download

Our

Our