- Purpose

- Characteristic

- Processing PDF

Dog food extruder is also called pet food extruder, which belongs to expanding dog food machine equipment.

Generally speaking, the dog food we often see in our daily life refers to dry expanded dog food, which also belongs to commercial dog food. Because of its comprehensive and balanced nutrition, easy digestion and absorption, long shelf life, convenient feeding and carrying, and affordable price, it is more and more accepted and sought after by people. This kind of dog food has been more and more deeply into many pet families.

With the popularization of scientific dog raising knowledge, the application scope of expanded dog food is gradually expanding, which makes the team of dog food manufacturing enterprises continue to grow, so the demand for dog food extruders is also growing.

What’s the main purpose of expanding dog food?

What’s the main purpose of expanding dog food?

1. Improve the palatability of pet food;

2. Change or improve the nutritional value of pet food;

3. Improve the digestion and absorption rate of pet food;

4. Change the shape and structure of pet food to make it easy for pet to eat;

5. Change the content of different nutritional indicators of pet food, such as: reduce the water content in order to improve the shelf life of food, which is conducive to storage;

6. Change the bulk density of the food, extrude and pelletize to increase the bulk density of the food;

7. Kill all kinds of mold, Salmonella and other harmful substances to improve the safety and hygiene of pet food.

What are the characteristics of the dog food extruder produced by our company?

What are the characteristics of the dog food extruder produced by our company?

The dog food extruder produced by our company is made of stainless steel, with reasonable structure, stable operation, low noise, reliable performance, simple operation and high equipment efficiency.

It consists of feeding system, extrusion system, rotary cutting system, heating system, transmission system and control system. Adopting advanced screw extrusion technology, materials are matured and expanded by high temperature and high pressure, which can be completed in one time. The main engine adopts frequency control to ensure the stability of the production process. The products are of various colors, varieties, beautiful appearance, fine texture and wide use of raw materials.

1.High temperature extrusion and expansion molding of twin-screw, effective sterilization and real realization of safety and health;

2.The host adopts frequency conversion control system, multiple effective parameters can be adjusted, and the processing quality can be reasonably controlled;

3.It can realize automatic and semi-automatic production configuration, continuous long-distance and continuous transportation, greatly improving work efficiency and saving cost for customers as much as possible;

4.Continuous belt back and forth oven is adopted for drying, with good drying effect;

5.The pet has good palatability, high molding rate, high production efficiency, good equipment stability, and is suitable for processing various formulations;

6.According to the customer’s needs, we can customize various shapes of molds and product exports.

Processing flow of dog food extruder:

Processing flow of dog food extruder:

Poultry meat chopping, mixing and crushing → mixing evenly → extrusion molding → cooking and setting → cutting into sections

(Dog food production line)

Product parameters:

Product parameters:

| Parameter of apparatus | |

| Power voltage | 380V/50HZ |

| Installed power | 60 KW |

| Power consumption | 45 KW |

| Production capacity | 180 – 220 Kg/h |

| Size dimension | 3.6× 1.0× 2m |

Why choose our company?

Why choose our company?

We are a large enterprise specializing in the production of various extrusion equipment. With the continuous efforts of professional engineers and employees, we have been working hard to develop new machinery.

Dog food extruder is a kind of machine developed by our company with reference to international advanced products of the same kind, which has been highly appraised and recognized by customers.

Our equipment has been sold all over the world for many years, such as Algeria, Egypt, India, Tanzania, Cote d’Ivoire, the Philippines, Russia, Ukraine, Australia, Argentina, Brazil, etc. many loyal customers test for you and purchase without worry.

- Installation of equipment in Brazil

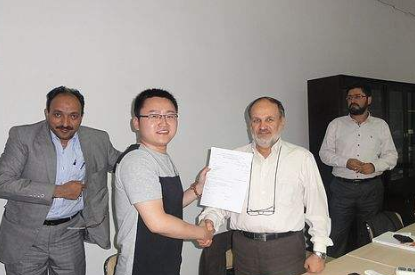

- Customer visit

Before and after the purchase, we will provide you with various consulting services free of charge, which can be customized according to your needs. We will send professionals to help you install and debug the dog food extruder at your site according to your needs. In addition, training personnel are also provided. We provide online service support for you. If you have any technical problems with the dog food extruder, please send us a message, we will provide the most professional technical guidance and lifelong maintenance.

If you visit, we will have professional technical service personnel to answer your questions. If you have any intention, please feel free to contact us!

Dog food extruder Technologies and Processing PDF Download

Dog food extruder Technologies and Processing PDF Download

What’s the main purpose of expanding dog food?

What’s the main purpose of expanding dog food?