In December,2018, we welcomed two customers from Iraq, and this time they came to our company to purchase fried snack production lines, make chips,bugles and so on.

We have a detailed explanation of this production line according to the customer’s request.

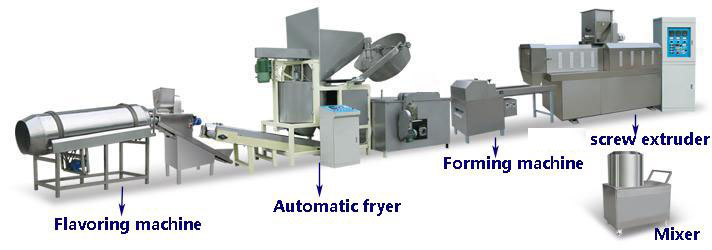

1.Production process and required equipment

- Mixer 2. Hoist 3. Double-screw mainframe 4. Plastic cutting machine 5. Frying pan (continuous frying pan) 6. Seasoning thread

According to the specific requirements of the customer, the frying pan can use a continuous frying pan, or flip the frying pan.

The output can be configured with double-screw 56,70, or 80 hosts per customer’s different needs, up to 300 kg/ hour

2.Rice crust/salad/bugles production line is a new technology of double-screw extrusion technology instead of traditional rice crust. The production line integrates mixing, ripening and expansion molding, and does not need boiler, simplified production process, high efficiency, environmental protection and low carbon.

3.Available raw materials: a wide range of raw materials can be used, customers can use local resources to make products.

It can be a single material such as rice flour, corn flour, flour and so on, or it can be a mixture of several kinds of flour. By changing the mold and molding machine, you can change the shape, strip (French fries), square, rhomboid, hemp, crispy pillow and wavy shape, etc. The produced pot bar, the salad bar, the salad piece, the sharp-pointed and crisp pizza roll, the shell cake, the cat’s ear and the taste and the crisp angle and the like are various, the product is vivid, the tissue is delicate, the taste is crisp, the extruded product can be directly fried, and the production process is simple and the production process is simple.

4.According to the requirements of our customers, we have produced rice crust samples, customers are very satisfied, he praised us as the best food machinery manufacturers in China! Now we have received orders from customers, in each link to control the quality, timely feedback to customers on the progress of production, so that customers can buy rest assured, must make good products, to provide the best quality service!